Mercedes-Benz Opens New MANUFAKTUR Studio in Sindelfingen, Expands MANUFAKTUR Range

[source: Mercedes-Benz]

“Made in Sindelfingen” is a traditional seal of quality for Mercedes-Benz customers. It refers to where top-of-the-range models such as the S-Class, which stand for precision and exclusivity, are produced in the ultra-modern Factory 56. However, Sindelfingen is not only the birthplace of the S-Class, it is also the home of MANUFAKTUR – the cross-brand individualization and personalization program of Mercedes-Benz. Here, specialized employees contribute their expertise in upholstery finishing, interior fittings, fabrication and special paintwork for customization of top-end vehicles. With the strategic further development of the MANUFAKTUR program, Mercedes-Benz continues the tradition of impeccable craftsmanship and enhances the role of Sindelfingen as a top-end vehicle manufacturing location.

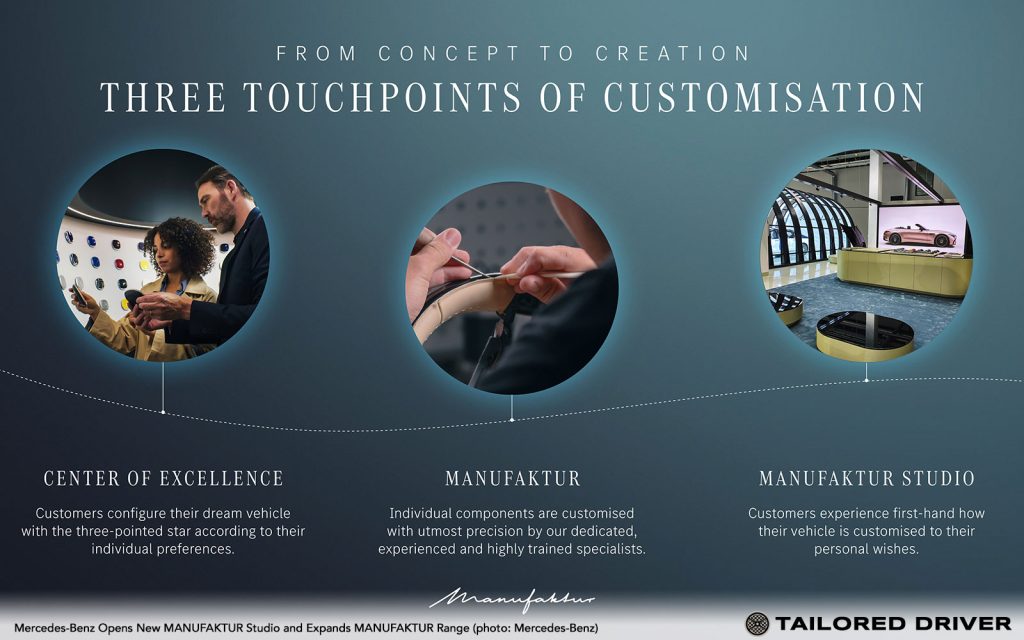

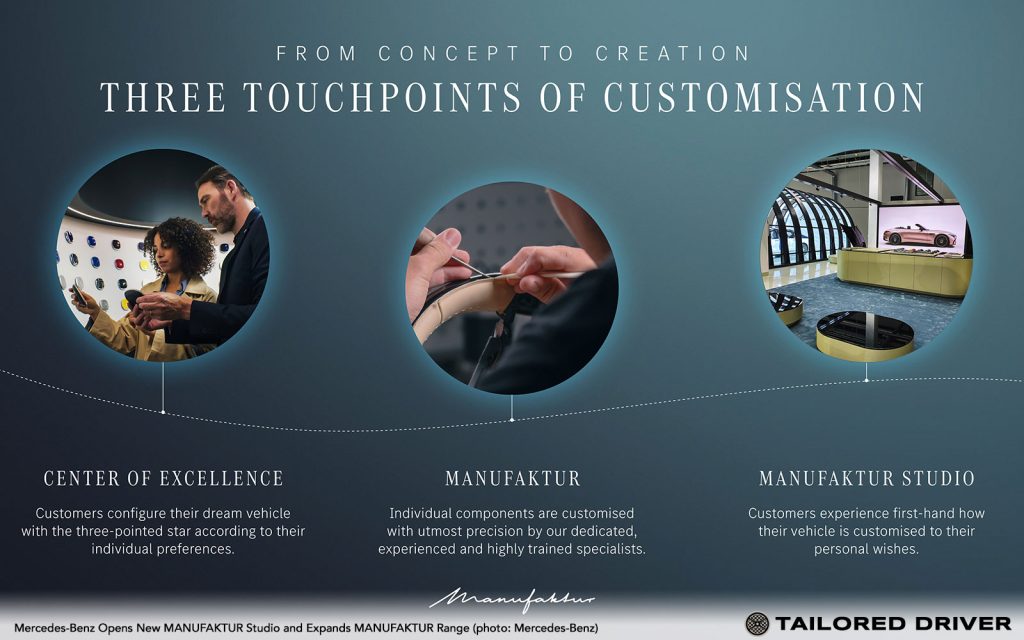

Customers with exclusive customization wishes can now experience the MANUFAKTUR program up close at several locations at the Sindelfingen site – at the traditional Center of Excellence, in the MANUFAKTUR and now also in the MANUFAKTUR Studio, which officially opened on December 5, 2024.

“In our new MANUFAKTUR Studio at the heart of the Sindelfingen factory complex, we’re offering our customers an exclusive area for a product experience with the highest degree of customization. By expanding the MANUFAKTUR experience, we are strategically developing the location and the ‘Made in Sindelfingen’ seal of quality. We’re now combining traditional craftsmanship with innovative, digital production processes.” Jörg Burzer, Member of the Board of Management of Mercedes-Benz Group AG, Production, Quality & Supply Chain Management

“Our MANUFAKTUR program offers discerning clients the opportunity to customize a selection of vehicles with the star according to their wishes. Whether it’s paints selected for the exterior or exclusive materials in the interior – thanks to MANUFAKTUR, there are numerous options for creating your personal dream car. Because of the program’s success, we are now expanding it further. In the new MANUFAKTUR studio, our customers can witness live how their wishes are turned into reality. Here, select equipment, which is handcrafted at MANUFAKTUR, is installed into its respective vehicle. We are also delighted to be able to offer a variety of new exclusive colors and interior equipment for the S-Class next year.” Michael Schiebe, Chairman of the Board of Management of Mercedes-AMG GmbH and Head of the Mercedes-Benz G-Class & Mercedes Maybach divisions

After customers configure their dream vehicle at the Center of Excellence, individual components are meticulously crafted by hand at MANUFAKTUR. In the new MANUFAKTUR Studio, customers can then experience first-hand how the vehicle is customized according to their individual wishes. Both locations combine craftsmanship, attention to detail and state-of-the-art production technologies to make individual vehicle dreams or even custom concepts a reality. At the same time, Mercedes-Benz is introducing innovative high-tech manufacturing methods and extensively expanding customization options.

MANUFAKTUR: skillful hands are the most valuable tools

The MANUFAKTUR team consists of experienced and extensively trained specialists. Their dedication to the craft is reflected in the outstanding quality of their work. Skilled hands are the most valuable tools here. Whether it’s leather cladding, cutting, embroidering or sewing – all interiors are finished with exquisite craftsmanship and the utmost precision. The production of small and intricate details is just as much at home here as the production of larger components. This includes, for example, a leather headliner, which is sewn together from many individual pieces.

The digitalization of individual work steps speeds up MANUFAKTUR processes and makes a significant contribution to quality assurance. Individual steps are also optimized with artificial intelligence. This can quickly and reliably detect small irregularities in leather hides, for example, and reduces the workload on employees.

The MANUFAKTUR Studio: individualization independent of series production

The innovative matrix production in the MANUFAKTUR Studio enables variable individualization of up to 20 vehicles per day, regardless of the model series. The highly flexible production structure has been completely reorganized. With the help of driverless transport systems that can move in any direction (autonomous guided vehicles, also known as “AGVs”), customer vehicles are transported between individual production clusters as required and independently of fixed sequences. Each of the nine clusters in the MANUFAKTUR Studio can be approached flexibly with the AGVs and operates independently of cycle times. In this way, the vehicle’s custom equipment can be installed effectively.

This is supported by the digital twin, which is used to monitor and, if necessary, optimize every stage of production. Last-minute changes are also possible. All production stations are networked via MO360, the in-house digital ecosystem for production. This means all production data can be accessed by every employee in real time via the MO360 data platform.

PixelPaint – an innovative high-resolution painting process for exclusive customer solutions

The innovative and resource-saving PixelPaint process revolutionizes the wide-ranging options for multi-colored vehicle paint jobs. Inspired by the function of an inkjet printer, this new technology applies high-quality paint directly onto the body of the vehicle with incredible precision. This allows for the application of custom patterns with the highest level of accuracy – ideal for individually designed dream vehicles. Customers can request bespoke design elements according to their ideas, which are limited only by technical feasibility.

Growing range for select top-end vehicles from the Mercedes-Benz Group

The MANUFAKTUR individualization and customization program consists of a growing range of equipment for select Mercedes-Benz, Mercedes-AMG and Mercedes-Maybach models. The MANUFAKTUR portfolio comprises an exclusive selection of materials, colors and finishes that go beyond standard options and create a highly individual experience. The focus here is on expanding the individualization options for customers in the top-end segment.

The S-Class will be available in the future with even more MANUFAKTUR Exclusive colors and further MANUFAKTUR options. As the Mercedes-Benz flagship, the S-Class exemplifies the extensive customization options of the MANUFAKTUR program. A similar expansion is also planned for select Mercedes-AMG and Mercedes-Maybach models.

About Mercedes-Benz USA

Mercedes-Benz USA (MBUSA), headquartered in Atlanta, is responsible for the distribution, marketing and customer service for all Mercedes-Benz products in the United States. MBUSA offers drivers the most diverse lineup in the luxury segment with 18 model lines ranging from the sporty GLA SUV to the flagship S-Class and the dynamic all-electric vehicles from Mercedes-Benz. MBUSA is also responsible for Mercedes-Benz Vans in the U.S. More information on MBUSA and its products can be found at www.mbusa.com and www.mbvans.com.

[…] and Singer aren’t alone. Brands such as Bentley, Mercedes-Benz and Rolls-Royce have publicized major efforts in expanding their own internal tailoring services […]